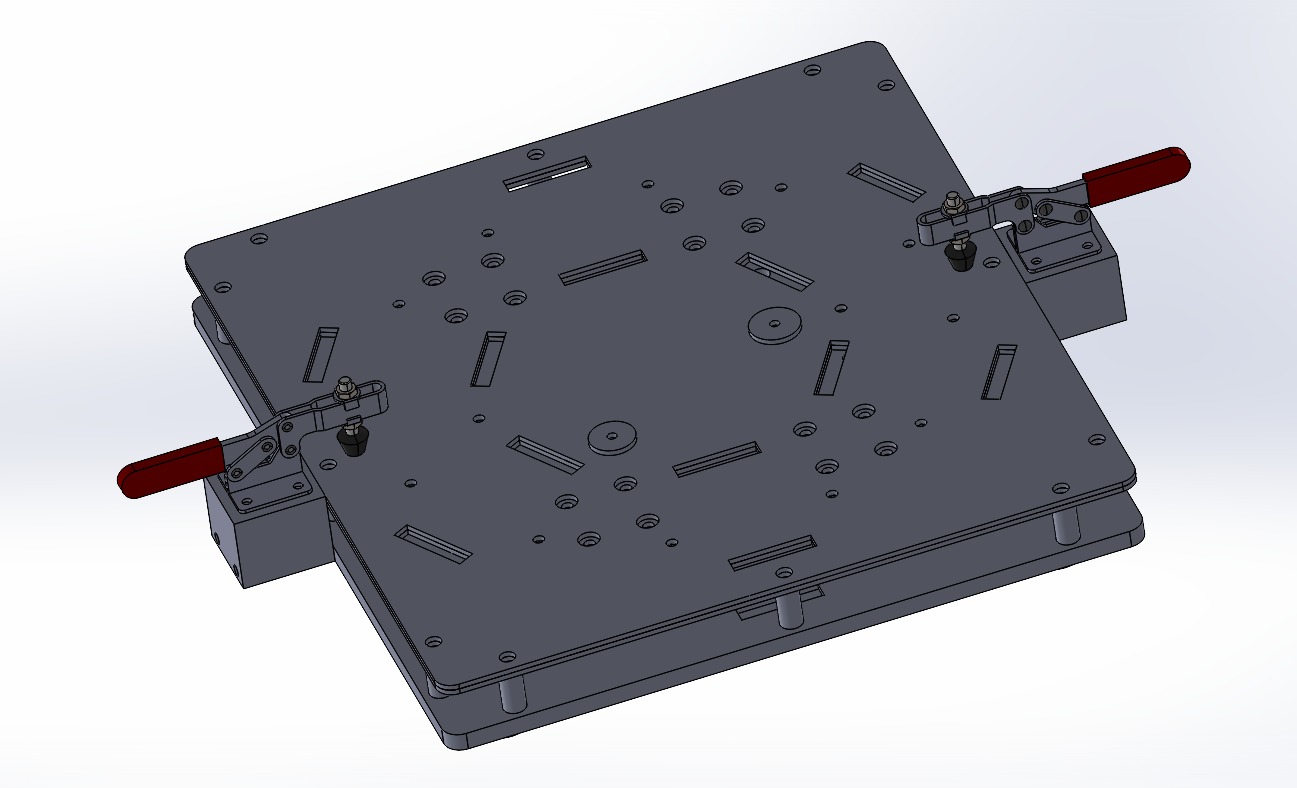

The Importance of Assembly Fixtures in Modern Manufacturing

18-December-24

In the world of manufacturing, precision, efficiency, and consistency are paramount. Assembly fixtures play a crucial role in achieving these objectives, acting as essential tools that streamline production processes and ensure high-quality outcomes. This blog explores the significance of assembly fixtures, their applications, benefits, and innovations shaping their future.

What Are Assembly Fixtures?

Assembly fixtures are specialized tools or devices used to hold, position, and align components during the manufacturing or assembly process. These fixtures ensure that parts are accurately placed and secured, allowing for seamless operations and repeatable results. Typically custom-designed, they cater to the specific needs of a product or assembly line, making them indispensable in industries like automotive, aerospace, electronics, and medical device manufacturing.

Key Benefits of Assembly Fixtures

- Enhanced Accuracy Fixtures eliminate variability by securely holding components in place, ensuring precision in assembly and reducing errors.

- Improved Efficiency By simplifying complex processes and reducing the need for manual adjustments, assembly fixtures speed up production cycles.

- Consistency in Quality Fixtures ensure that each product meets the same high-quality standards, critical for industries requiring tight tolerances.

- Increased Worker Safety By securely holding parts, fixtures minimize the risk of accidents caused by slipping or misaligned components.

- Cost Savings Fixtures reduce material waste and rework caused by errors, contributing to significant cost savings over time.

Applications of Assembly Fixtures

Assembly fixtures are versatile tools with applications across various industries:

- Automotive: Used for welding, assembling, and inspecting components like chassis, engines, and interior parts.

- Electronics: Assist in the precise placement of circuit boards, connectors, and microchips.

- Aerospace: Ensure the alignment and assembly of complex components like fuselages, wings, and landing gear.

- Medical Devices: Enable the accurate assembly of intricate devices like surgical tools, implants, and diagnostic equipment.

- Consumer Goods: Streamline the assembly of appliances, furniture, and other household items.

Types of Assembly Fixtures

- Welding Fixtures Used to position and hold parts during welding, ensuring strong and accurate joints.

- Inspection Fixtures Help verify dimensions, alignments, and tolerances, ensuring that components meet quality standards.

- Drilling Fixtures Guide drilling operations with precision, ensuring accurate hole placement.

- Vacuum Fixtures Use suction to hold delicate components in place, often used in electronics or glass manufacturing.

- Modular Fixtures Highly adaptable fixtures that can be reconfigured for different tasks, ideal for prototyping or low-volume production.

Innovations in Assembly Fixtures

The field of assembly fixtures is evolving rapidly, driven by advancements in technology:

- 3D-Printed Fixtures Additive manufacturing allows for the rapid production of custom fixtures, reducing lead times and costs.

- Smart Fixtures Integrated with sensors and IoT technology, these fixtures provide real-time feedback, enabling predictive maintenance and quality control.

- Adjustable Fixtures These fixtures use automation to adapt to different components, enhancing flexibility in multi-product assembly lines.

- Lightweight Materials New materials like carbon fiber are making fixtures lighter and easier to handle without compromising strength.

The Future of Assembly Fixtures

As industries move towards smarter and more automated manufacturing processes, the future of assembly fixtures looks promising:

- AI-Powered Fixtures: Artificial intelligence will enable fixtures to self-adjust and optimize assembly processes.

- Integration with Robotics: Fixtures will increasingly work in tandem with robots, creating fully automated assembly systems.

- Sustainable Materials: Eco-friendly materials will become more prevalent, aligning with green manufacturing initiatives.

- Digital Twins: Virtual models of fixtures will allow manufacturers to simulate and optimize designs before production.

Conclusion

Assembly fixtures are foundational to modern manufacturing, enabling precision, efficiency, and consistency across industries. As technology continues to advance, these tools will become even more sophisticated, adaptable, and integral to the production process. By investing in innovative fixtures, businesses can enhance their competitiveness and meet the ever-growing demands of today’s markets.

Innov Touch Technologies Pvt Ltd.

Innov Touch Technologies Pvt Ltd.