Key Features:

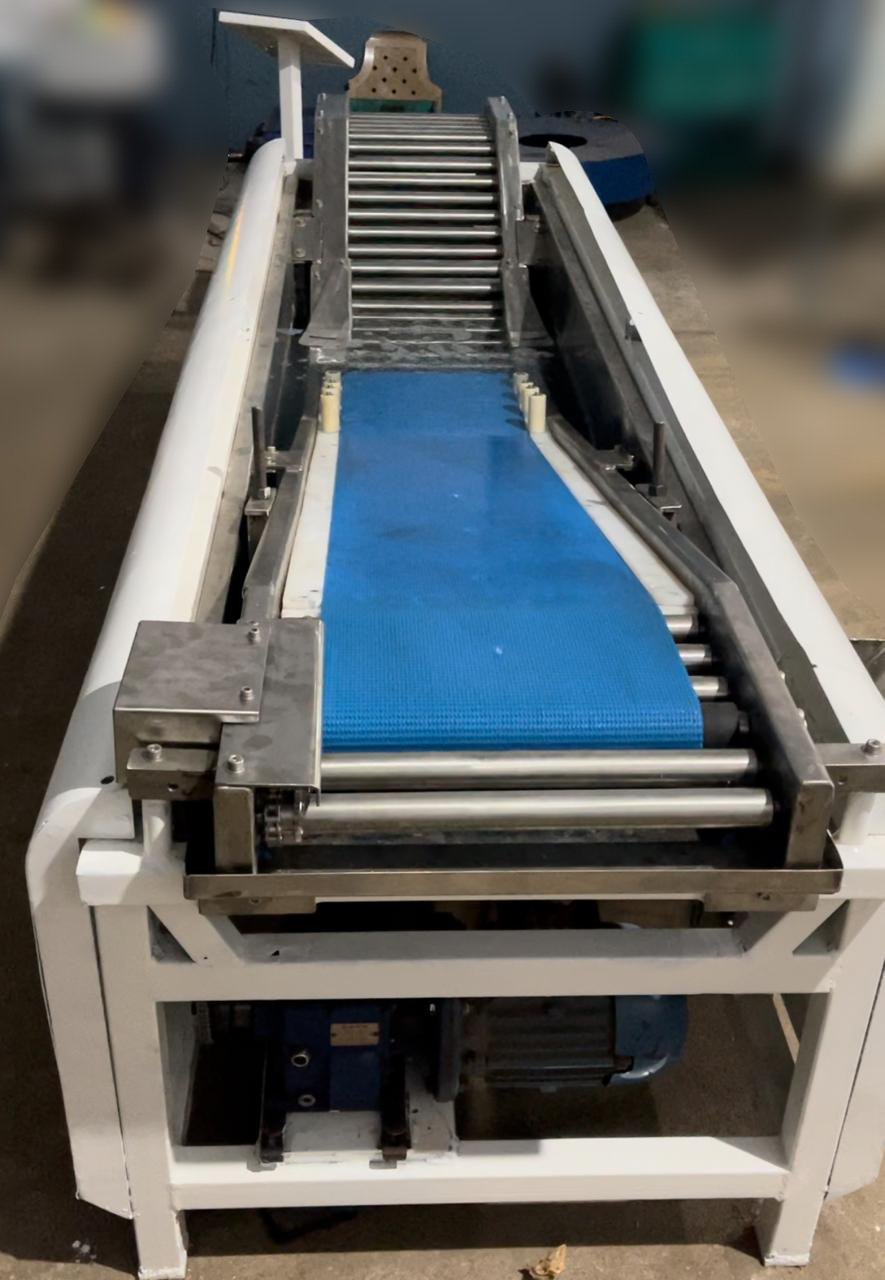

- Heavy-Duty Construction:

Built to withstand the rigors of industrial environments, our conveyor lines are made from high-quality materials like steel, stainless steel, and durable polymers to ensure long-lasting performance.

- Customizable Designs:

Available in a variety of configurations, including belt conveyors, roller conveyors, chain conveyors, and overhead conveyors, to suit different material handling requirements.

- Variable Speeds and Adjustable Control:

Integrated control systems allow for adjustable speeds, ensuring the right pace for different stages of your production process.

- Space-Efficient Layouts:

Our conveyors can be designed to fit seamlessly into your existing production floor, optimizing space while maintaining a smooth flow of goods.

- Modular and Scalable:

Easily expandable and adaptable to meet growing business needs, allowing you to upgrade your system without major downtime or disruption.

- Low Maintenance and Durable:

Designed for minimal maintenance and built for high-volume operations, ensuring maximum uptime and reduced operational costs.

Benefits:

- Increased Efficiency and Productivity:

Automates the material transport process, reducing downtime and speeding up the flow of goods through your facility, leading to higher output and throughput.

- Labor Cost Reduction:

By minimizing manual material handling, you can reduce labor costs and free up staff for more value-added tasks, improving overall workforce productivity.

- Improved Safety:

Conveyor lines reduce the risk of workplace injuries by minimizing the physical strain on workers, promoting a safer and more ergonomic environment.

- Enhanced Product Consistency:

Conveyor systems ensure a smooth, consistent flow of materials, improving product quality and reducing errors during transport or assembly.

- Flexibility for Different Applications:

Suitable for a wide range of industries, including automotive, food processing, pharmaceuticals, logistics, and more, with options for handling various sizes, weights, and types of products.

Applications:

- Manufacturing & Assembly Lines:

Transport raw materials, parts, or finished products efficiently through different stages of assembly, testing, or packaging.

- Warehousing & Distribution:

Streamline the movement of products in distribution centers, from sorting to packaging and shipping.

- Food & Beverage Processing:

Ensure efficient, hygienic transport of raw materials, ingredients, and finished goods throughout the production process, maintaining food safety standards.

- Pharmaceutical & Medical Device Manufacturing:

Transport sensitive materials and products in compliance with industry regulations, ensuring precision and reliability throughout production and packaging.

- Automotive & Heavy Equipment Manufacturing:

Efficiently move large or heavy components through assembly lines, welding stations, or testing areas, reducing manual handling and optimizing workflow.

Why Choose Our Industrial Conveyor Line Systems?

With years of expertise and a commitment to innovation, we offer industrial conveyor solutions that are reliable, scalable, and tailored to your specific needs. Our systems are designed to boost productivity, reduce costs, and enhance the safety and efficiency of your operations.

Optimize your operations with our industrial conveyor line systems—efficient, durable, and customizable to fit your business needs!

Innov Touch Technologies Pvt Ltd.

Innov Touch Technologies Pvt Ltd.