Key Features:

- Precise Component Positioning:

Our indexing fixtures are engineered to hold parts in exact, repeatable positions, ensuring accurate and efficient assembly operations.

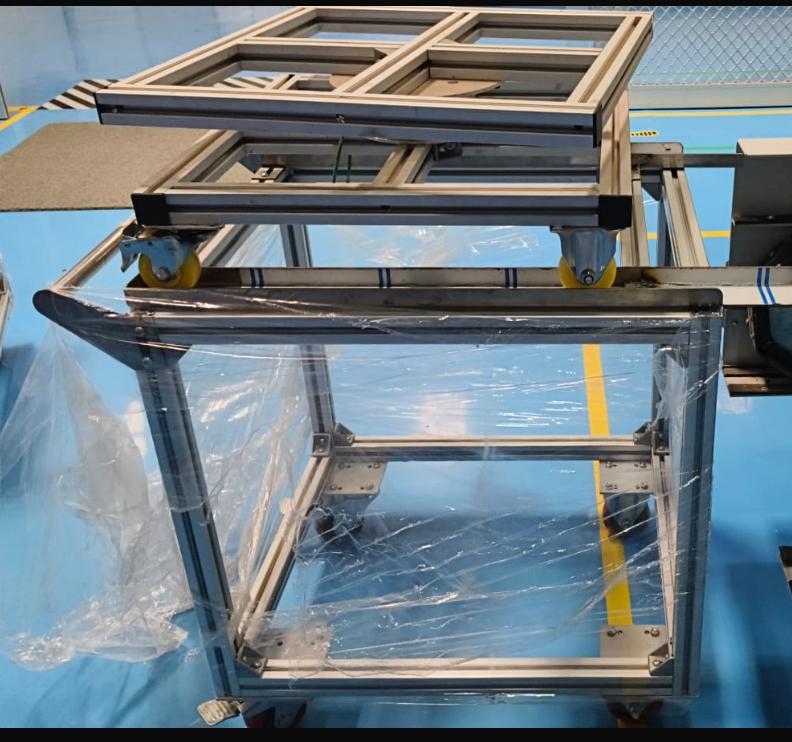

- Modular Design:

Customizable to fit your specific assembly needs, indexing fixtures can be adjusted or reconfigured to accommodate different parts, enhancing flexibility on your production line.

- Automated or Manual Operation:

Available in both manual and automated versions, allowing you to choose the level of automation that best fits your operational needs.

- Durable Materials:

Made from high-quality, wear-resistant materials such as steel and aluminum, our indexing fixtures are built to withstand the demanding conditions of continuous use.

- Smooth Indexing Mechanism:

Advanced indexing mechanisms ensure smooth, reliable transitions between stages, minimizing delays and keeping the assembly line moving efficiently.

- Easy Integration:

Designed to integrate seamlessly with existing assembly lines, reducing setup times and optimizing your overall production process.

Benefits:

- Increased Production Speed:

The precise positioning and fast transitions between stages help speed up the assembly process, increasing throughput and reducing cycle times.

- Improved Accuracy and Consistency:

Indexing fixtures guarantee that components are always placed in the same position, ensuring high-quality assembly and minimizing errors.

- Reduced Labor Costs:

By automating the positioning and rotation of parts, indexing fixtures reduce the need for manual intervention, allowing workers to focus on higher-value tasks.

- Enhanced Safety:

These fixtures minimize human interaction with moving parts, reducing the risk of workplace injuries and promoting a safer work environment.

- Flexibility for Various Applications:

Ideal for a wide range of applications, including electronics, automotive, and consumer goods manufacturing, our indexing fixtures are adaptable to many different products and production requirements.

Applications:

- Electronics Assembly:

Ensure precise placement of small and delicate electronic components during assembly, soldering, and testing.

- Automotive Assembly:

Position automotive parts for tasks such as welding, screwing, and quality inspections, improving production speed and accuracy.

- Consumer Goods Manufacturing:

Used in the assembly of a wide variety of consumer products, including home appliances and personal devices, for consistent, high-quality results.

- Medical Device Manufacturing:

Ideal for the precise assembly of medical components, ensuring product consistency and meeting industry standards.

- Industrial Equipment Assembly:

Helps position large, heavy components in place for accurate and efficient assembly, welding, or inspection.

Why Choose Our Indexing Fixtures?

Our indexing fixtures are built to improve the accuracy, efficiency, and speed of your assembly line. With durable materials, customizable options, and smooth, automated operation, they provide the flexibility you need to adapt to changing production requirements while reducing costs and increasing output.

Maximize your assembly line’s performance with our indexing fixtures—delivering precision, reliability, and efficiency at every stage!

Innov Touch Technologies Pvt Ltd.

Innov Touch Technologies Pvt Ltd.